Singtex Group has always focused on "environmental sustainability" through our core products and by unleashing our competences. We strive to promote green product design & development, green production, and a green supply chain. Inspired by the values of a "business that warms the heart", we take proactive measures to mitigate the impact of climate change on people's survival, such as investing several hundred million dollars to create the pioneering R&D center and precision eco-friendly dyeing and finishing R&D center. The Company's products has not only received the Taiwan Excellence Award, Taiwan Mittelstand Award, and 3 major international accolades, but also passed OEKO-TEX®, GRS, and the most stringent Swiss bluesign® certification, demonstrating our commitment to environmental policies.

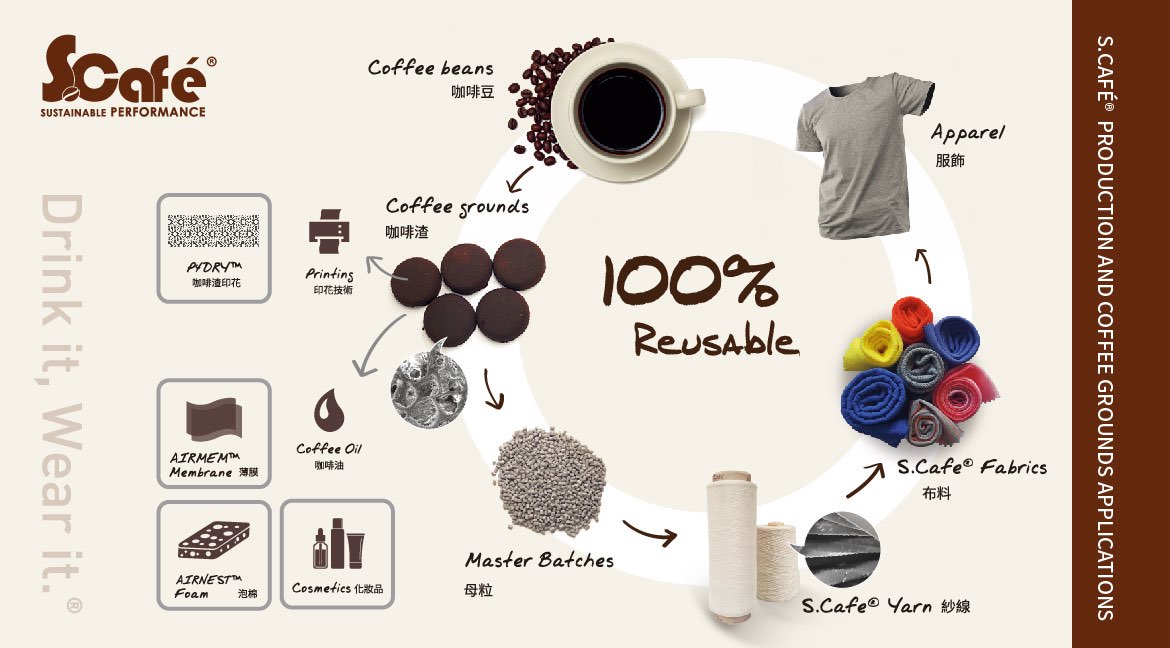

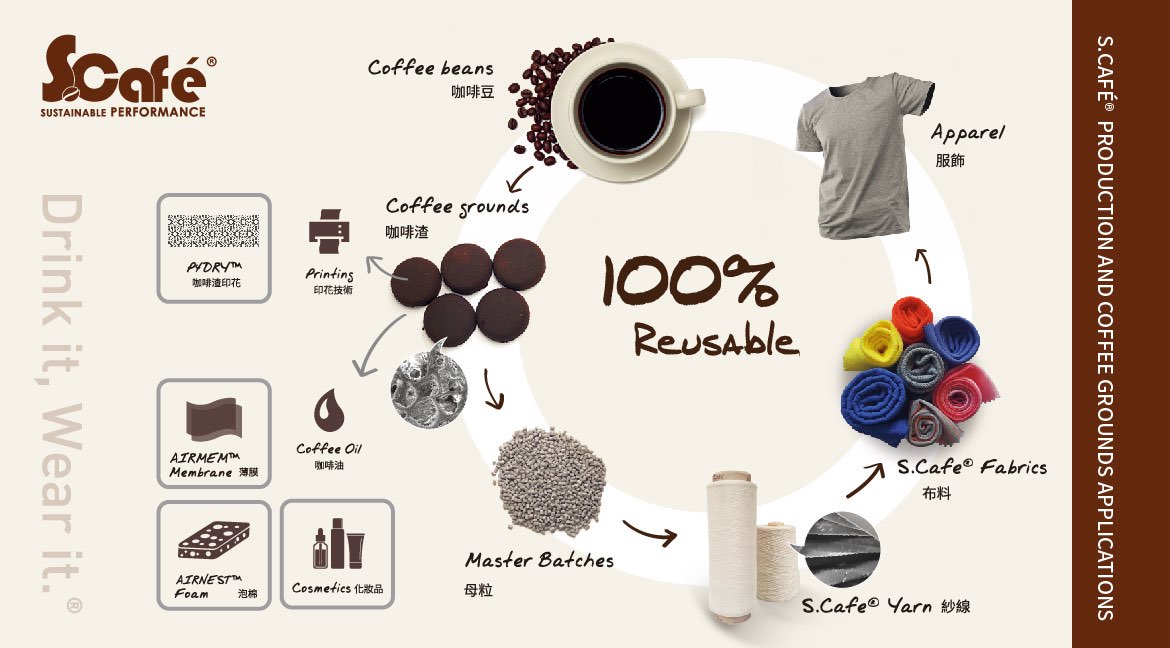

S.Café® sustainable technology is integrated into our ever growing coffee drinking culture. There is never a need to waste time and energy to produce the essential S.Café® raw material, as there is always coffee being consumed, therefore there will always be coffee grounds to be collected and used. S.Café® yarn can be used in a variety of different products, from outdoor and sports performance apparel, to household items we use every day. There is an endless possibility where we are able to apply our sustainable material. By making less of an impact on our environment, we are making the world a better place for the next generation.

Materials from waste, reducing the burden on the earth.

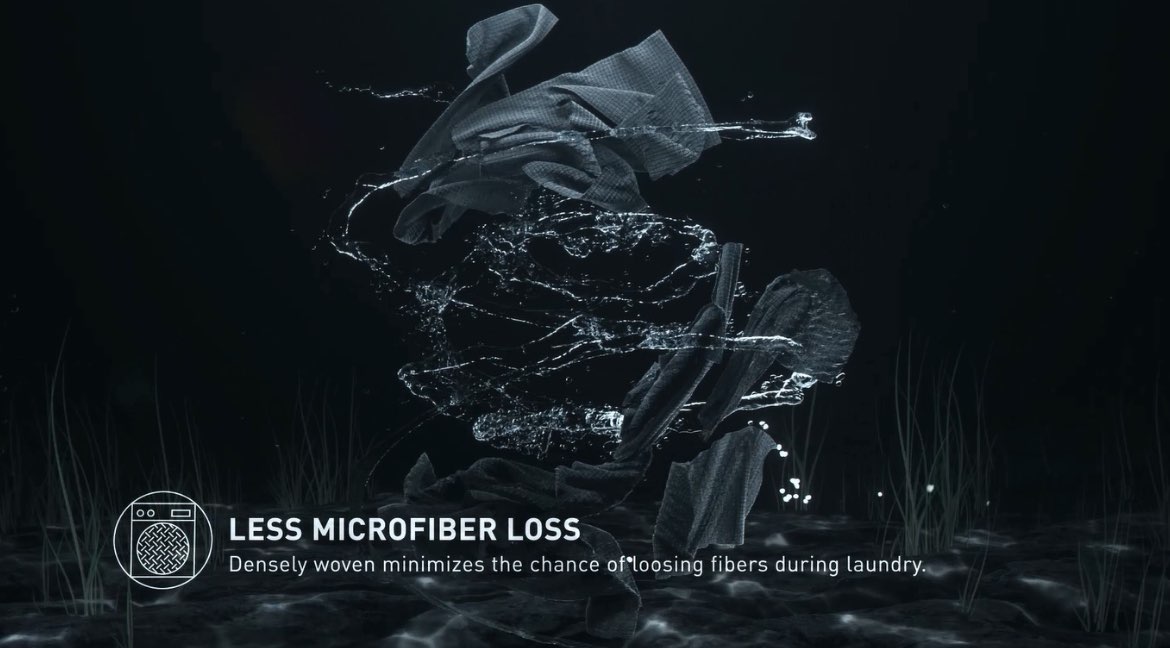

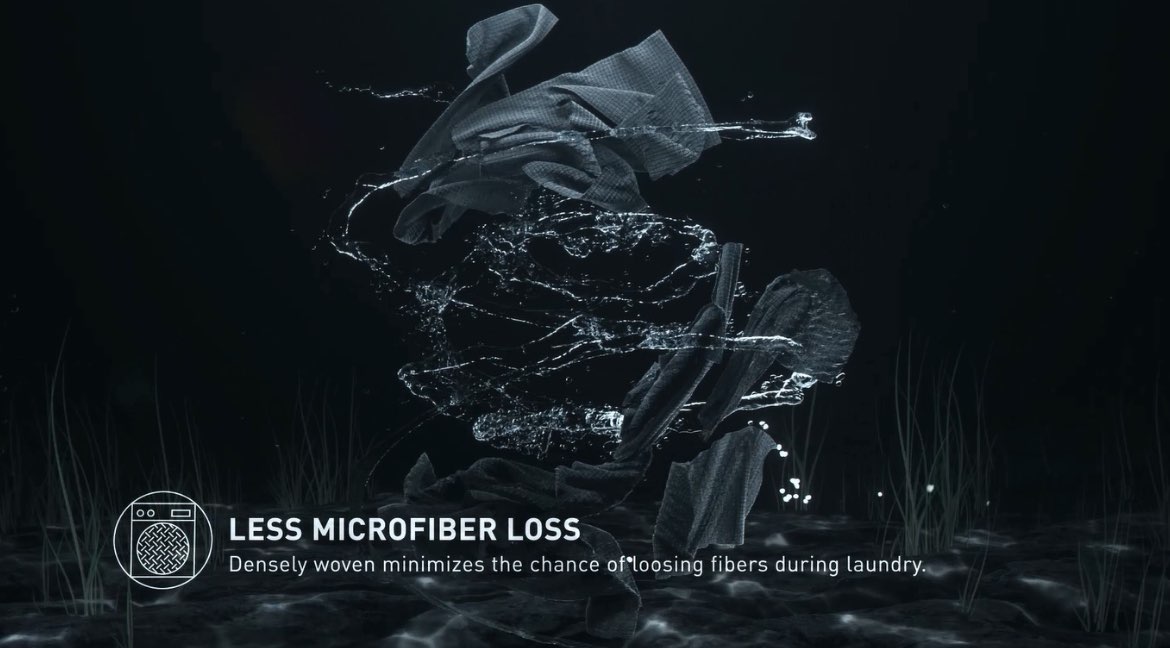

Regular 2 or 3 layer knitted fabrics tend to shed more microfibers during laundry due to delamination or loose knitting. With STORMFLEECE™'s unique single layer woven construction, fibers are tightly fabricated together minimizing the amount of fibers going down the drainage.

PATENTED TECHNOLOGY

Patent Number: TW I630296

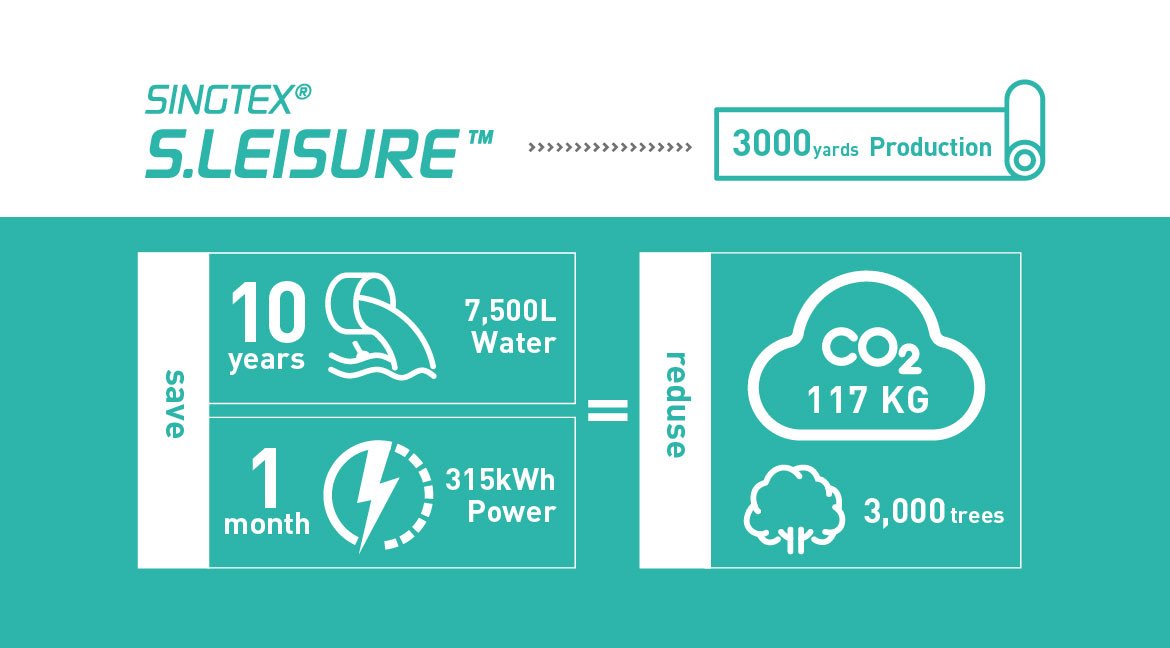

S.LEISURE™ is a supreme standard for comfort fabrics that offers stretch-ability and flexibility to the wearer while minimizing impact to the environment. At least 20% more energy efficient that spandex fabrics.

ONESHELL™ is built around the philosophy that simple is beautiful. We have developed a mono-material method of manufacturing a wide range of fabrics, including 2 and 3-layer waterproof and breathable fabrics, from one single polymer.

A wide range of ONESHELL™ textiles are available including face, membranes and backers. Garments made from a single material can be regenerated through end-of-life recycling.

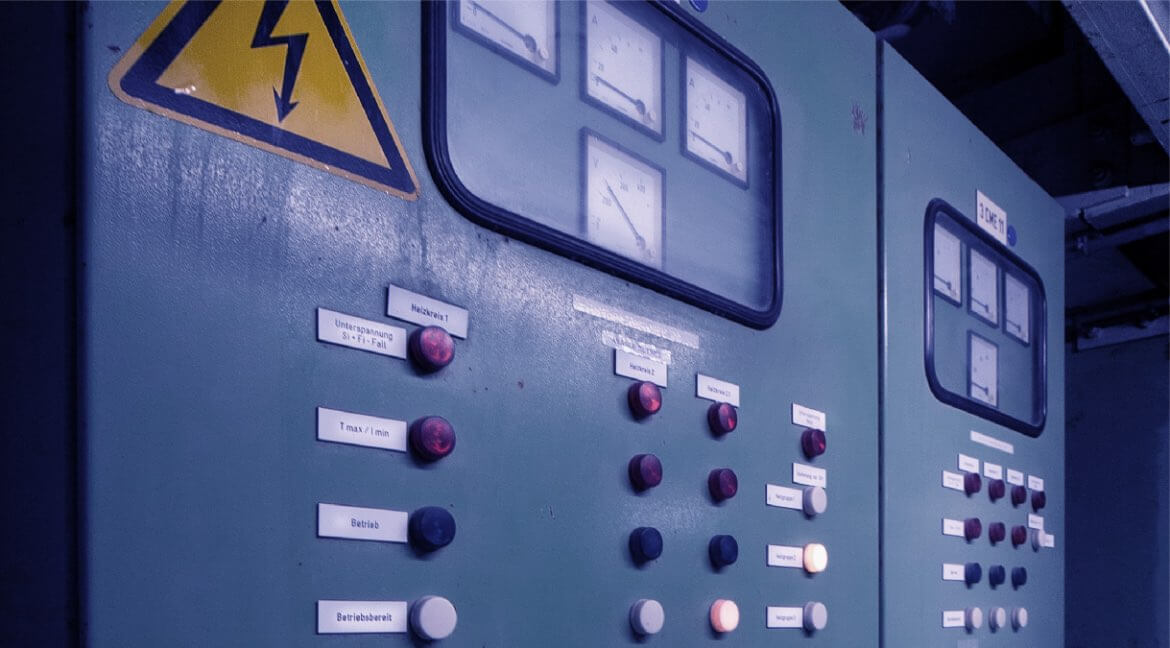

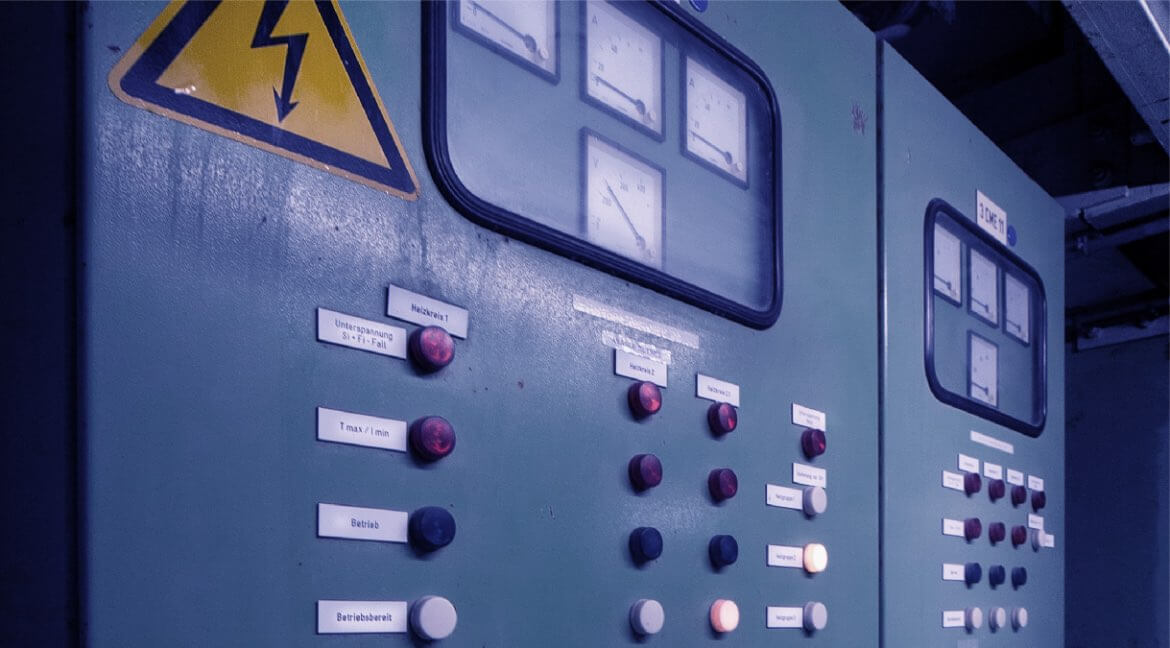

Environmental engineering approach was introduced during the early stages of the factory construction, where solvent-free dyeing process, natural gas reduction (lower carbon emissions), and energy-saving machines were implemented. Besides FTC's intelligent energy-saving system, we also introduced the sewage treatment system along with water-saving dyeing machine and waterless color yarn technology to ensure the efficient utilization of water. In total, the steam, water, and electricity-saving measures reduce carbon emissions by 796.2 tons/year.

Waterless color yarn technology enhances color fastness and resolves the risk of dye migration.

The solvent–free dyeing process is friendly to the Earth and the environment, which decreases bodily harm caused by chemical fabrics.

Computerized laboratory and on-site color matching to reduce artificial errors and stabilize the color.

Comparing to traditional machines, it consumes only one third of the energy and save 70% of the water. Save 319,488 kilowatt-hours of electricity annually, reducing carbon emissions by 796.2 tons.

It replaces traditional kerosene and reduces the carbon footprint by 50%.

Sewage is being recycled and reused to reduce pollution.

Smart comprehensive monitoring on energy usage and production lines to stabilize production quality and reduce risks.

Heating recycling system can reuse 30% of the heat energy.

The establishment of an energy monitoring system helps the company to control energy use, thereby improving and enhancing the efficiency of energy use.

Improving the heat exchanger and valve insulation facilities of the dyeing machine can reduce the use of natural gas by 334,717 degrees per year and reduce carbon dioxide emissions by 706.6 tons.

The solar power generation system of Guanyin dyeing and finishing factory currently under construction, It is expected to reduce carbon emissions by 106.65 metric tons per year after completion; The afforestation benefit is about 10.75 hectares per year.

The whole factory of GFun uses solar energy, covering an area of 7,500 square meters. It can replace 23.5% of the whole factory's energy. It is the first waterproof and moisture-permeable factory in Taiwan with world-class environmentally friendly energy equipment.

Energy conservation, carbon reduction, and cherishing the Earth has become a global trend. In continuing to promote the philosophy of energy conservation and carbon reduction, Singtex will keep on implementing various water-saving, power-saving, and renewable resource measures. By formulating specific energy conservation and carbon reduction measures, we encourage our colleagues not only to engage in these measures in the office but also at home, thereby expanding the influence of the earth-friendly movement to every corner of the world.

For our green energy initiative,We spent NT$11.77 million to purchase 1,850 solar panel modules and related equipment on May 26, 2022.

along with expanding the existing solar power facility.While deepening roots in Taiwan, the company also aims to fulfill corporate social responsibility,contributing to Taiwan's sustainable environment.

SINGTEX High-end Precision Dyeing and Finishing Factory is located in Guanyin Industrial Zone, Taoyuan City. With a commitment to safeguarding the local environment, we have been adopting roadside trees for nine consecutive years and planting numerous plants within the factory premises. Our aim is to attract native birds and butterflies, thereby fostering a green environment within the factory.

SINGTEX® has been supplying S.Café® fabric to make Tianzhong Marathon running clothes for seven years. The fabric is sourced from waste coffee grounds and added to the fiber through patented technology to achieve odor control, UV resistance and quick-drying effects.

In 2022, SINGTEX® launched the "REFIT™ Textile Recycling Project" at the Tianzhong booth, encouraging runners to bring 100% polyester running clothes they no longer wear to the booth and hand them over to SINGTEX® to be made into brand new clothes.

Implement the "Textiles to Textiles" sustainable recycling plan!

By 2023, the Company has adopted rice fields in Yilan for 13 straight years. The rice fields adopt the philosophy of environmental protection, where organic farming methods are applied to fertilizing and weed; our employees are invited to participate in the rice seedling transplanting and harvesting experience, caring about the land by taking action. The organic rice harvested from the rice fields is used as Moon Festival souvenirs.

SINGTEX® REFITTM is a new sustainable recycling project.

We recycle end-of-life 100% polyester garments and textile scraps from clothing manufacturing. Through a depolymerization process, SINGTEX® REFIT™gives old clothes a new life.

Singtex cares about the local environment, hence we helped the The Society of Wilderness to obtain grants from Patagonia, a designer of outdoor clothing and gear and also a client of Singtex. The fund is used to conduct environmental education promotion at the Wugu Wetlands and Shuanglian Reservoir Wetlands.

您的訊息已寄出,我們會盡快回應您的需求

Your message has been sent, and we will respond to your request as soon as possible.